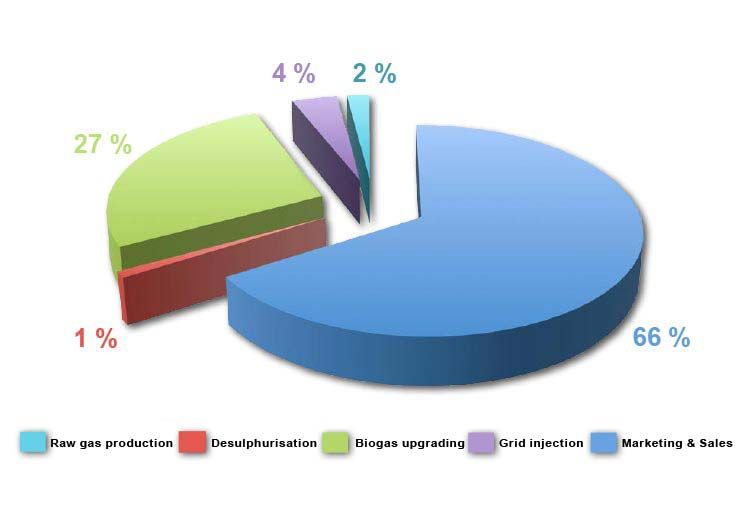

Comparing to previous technologies such as pressurized water scrubbing, pressure swing absorption or amine scrubbing, Gas Separation Membrane is relatively simple technology with high efficiency, and its operating cost is the lowest !

Futhermore, moisture contained in the gas is also removed as a side effect of the membrane separation process ;therefore, there is no subsequent gas drying for feeding into the grid required.

Due to the compact construction this technology is particularly suitable to upgrade biogas plants with existing cogeneration units, or to replace old, depreciated cogeneration units without adequate energy recovery.

Ideal if only a subset of a biogas production should be upgraded into biomethane.

The off-gas is then recycled again and added into the fermenter, the down streamed cogeneration unit can compensate the reduced methane concentration without any problems; the efficiency of the gas engine decreases only slightly.

The operation of Bio CNG service stations - even in intermittent operation - is the primary area of operation for this process concept - but also with this design the feeding into the public gas grid is possible.

Here the highly selective membrane modules are arranged so, that both product gas as well as off gas are each be concentrated several times.

Such a methane slip of less than 0.5% can be achieved.

With this concept, the maximum methane yield is guaranteed, while ensuring the lowest emissions.

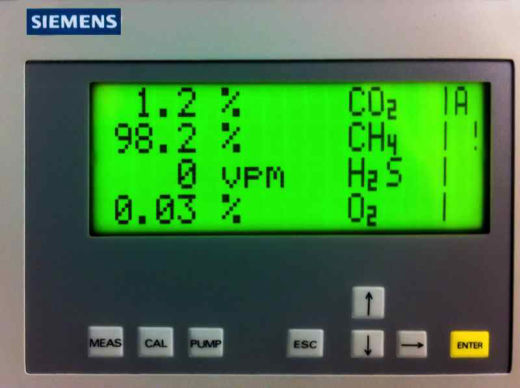

Biogas plant with raw gas capacity of 500 Nm³/h. Gas processing via 3-step BioMem membrane separation process with Membrane Module SEPURAN® Green from Evonik.

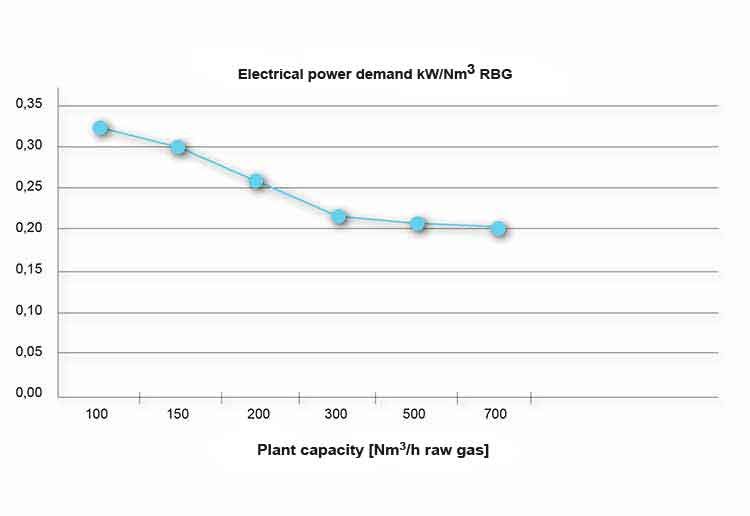

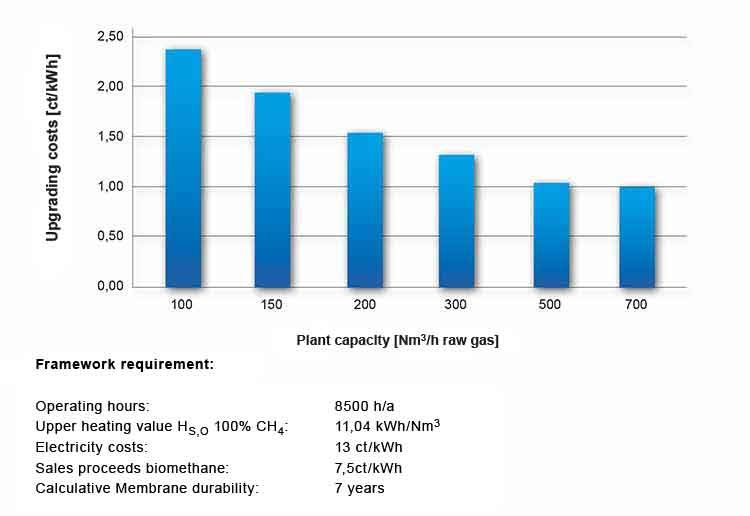

Ranges from 100 to 700 (Nm³/h raw gas)

Specific gas processing costs pro kWh.

(Product gas quality >98%, 3-step process).

Applying the latest technology from EVONIK for Natural Gas/Biogas Production, Refinery Operation, Petrochemical Processes, Pharmaceutical and Essencial Oil Production Plant.Evonik is the global leader in membrane systems for the six below categories (1) Bulk, Oil-&Petro Chemistry, (2) Natural Gas, (3) Biogas, (4) Refinery and Syngas, (5) Fine Chemistry, Pharmaceutical and (6) Natural&Essencial Oil

Click below button to learn more about these innovative products from Evonik.